-

Our Services

- AI with HKPC PICASSO

- The Cradle – Go Global Service Centre

-

New Industrialisation

- New Industrialisation

- New Productive Forces Service Platform

- Smart Production Line

- Innovation Technology and R&D

- Transformation and Upgrading

- Nurture New Industrialisation Talent

- Rules and Regulations

-

HealthTech and Traditional Chinese Medicine

- HealthTech and Traditional Chinese Medicine

- R&D service and Functional Investigation on Chinese Medicine, Health Food & Wellness product

- Compliance Consultation Service for Chinese Medicine, Pharmaceutical, Health Food and Medical Device Industries

- Manufacturing Enhancement - Automatic Intelligent System for Production and Packaging in Chinese Medicine, Pharmaceutical and Health Food Industries

- Assisting funding application for local medicine and health industrial associations

- “The Cradle” Services for Health Tech and TCM Industry

-

Smart Manufacturing

- Smart Manufacturing

-

IIOT

- IIOT

- Industrie 4.0 - Smart Enterprise

- Product Lifecycle Management Consultancy

- Intelligent Automatic Warehousing and Logistics

- Real-Time Manufacturing Tracking System

- Knowledge Based Engineering & CAD Solution

- Location Based Services and Location Analytics

- The HATCH

- Hong Kong Industrial Drone Technology Centre

- Novel Materials

-

Advanced Manufacturing Technology

- Advanced Manufacturing Technology

- 3D Scanning and Reverse Engineering Service

- Flexible Metallic Fiber Physical Porous Part Fabrication Technology

- Advanced Mould Cooling Technology and CAE Conformal Cooling Analysis

- Gas Atomisation Technology

- Dual Laser Metal Polishing Technology

- Advanced Additive Manufacturing, 3D Printing Technology, and Direct Manufacturing

- Diffusion Bonding Technology

- Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

- Plastic Process and Machinery Technology

- Fashion and Garment Technology

- Computer Aided Technology (CAx)

- Watch Assembly Automation Technology

-

Digital Transformation

- Digital Transformation

- HKPC Digital DIY Portal

- Digital Transformation Support

- Intelligent Integrated Non-wearable and Wearable Health Monitoring System and App for Elderly Homes

- 「FitEasy」Virtual Fitting Technology - For People with Disability

- Smart Solution

- Research and Analytics

- Strategic IT Management

- Embedded Software System

- New Media and Learning Technology Development

- IT Industry Support

- DevOps Maturity Assessment and Consultancy Service

- Software Testing Automation Consultancy Service

- Blockchain Consulting Service

- Extended Reality (XR) technology and consultancy service

-

Cyber Security

- Cyber Security

- Cyber Security

- Cybers Security-by-design, Privacy and Compliance-by-default

- Design & Architecture

- Train & Develop

- Offensive Security

- Intelligent Security

- Defensive Security

- Intelligent Hardening

- Internet of Things (IoT) & Operational Technology (OT) Cyber Security Testing

- Phishing Defence Services

- Cyber Security Assessment & Audit

- Cyber Security Consultancy for i4.0 & e4.0

-

Green & Smart Living

- Green & Smart Living

- Green Technology

- Food Technology

- Smart Living

-

Corporate Sustainability

- Corporate Sustainability

- ESG and Sustainability Services

- Manufacturing Technology (Tooling, Metals & Plastics) Recognition of Prior Learning (RPL) Mechanism

- Market Research and Analytics

- Business Innovation

- Sustainability-related standards and guidance

- Organisation Innovation Capability Development

- District Innovation

- Customer Service Assessment

- Intellectual Property (IP) Protection and Management

- Support to Creative Industries

- Manufacturing Standards Consultancy Service

- Production Capacity Optimisation

- Cost of Quality

- HKPC Academy

- SME Support

- Funding

- Testing & Standards

- Venues & Facilities

-

Support & Resource

- Technology Transfer

-

Support Centres

- Support Centres

- Low-altitude Economy Tech Hall

- The Cradle – Go Global Service Centre

- Agentic AI and Industrial Metaverse Hall

- HKPC-HP 3D Printing Technology Centre

- Future Manufacturing Hall

- Hong Kong Technology and Innovation Support Centre

- Inno Space

- The HATCH

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

- Testing & Standards

- HKPC Spotlights

- About US

-

LANGUAGE

LANGUAGE

HealthTech and Traditional Chinese Medicine

- R&D service and Functional Investigation on Chinese Medicine, Health Food & Wellness product

- Compliance Consultation Service for Chinese Medicine, Pharmaceutical, Health Food and Medical Device Industries

- Manufacturing Enhancement - Automatic Intelligent System for Production and Packaging in Chinese Medicine, Pharmaceutical and Health Food Industries

- Assisting funding application for local medicine and health industrial associations

- “The Cradle” Services for Health Tech and TCM Industry

IIOT

- Industrie 4.0 - Smart Enterprise

- Product Lifecycle Management Consultancy

- Intelligent Automatic Warehousing and Logistics

- Real-Time Manufacturing Tracking System

- Knowledge Based Engineering & CAD Solution

- Location Based Services and Location Analytics

- The HATCH

- Hong Kong Industrial Drone Technology Centre

Advanced Manufacturing Technology

- 3D Scanning and Reverse Engineering Service

- Flexible Metallic Fiber Physical Porous Part Fabrication Technology

- Advanced Mould Cooling Technology and CAE Conformal Cooling Analysis

- Gas Atomisation Technology

- Dual Laser Metal Polishing Technology

- Advanced Additive Manufacturing, 3D Printing Technology, and Direct Manufacturing

- Diffusion Bonding Technology

- Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

- Plastic Process and Machinery Technology

- Fashion and Garment Technology

- Computer Aided Technology (CAx)

- Watch Assembly Automation Technology

Digital Transformation

- HKPC Digital DIY Portal

- Digital Transformation Support

- Intelligent Integrated Non-wearable and Wearable Health Monitoring System and App for Elderly Homes

- 「FitEasy」Virtual Fitting Technology - For People with Disability

- Smart Solution

- Research and Analytics

- Strategic IT Management

- Embedded Software System

- New Media and Learning Technology Development

- IT Industry Support

- DevOps Maturity Assessment and Consultancy Service

- Software Testing Automation Consultancy Service

- Blockchain Consulting Service

- Extended Reality (XR) technology and consultancy service

Cyber Security

- Cyber Security

- Cybers Security-by-design, Privacy and Compliance-by-default

- Design & Architecture

- Train & Develop

- Offensive Security

- Intelligent Security

- Defensive Security

- Intelligent Hardening

- Internet of Things (IoT) & Operational Technology (OT) Cyber Security Testing

- Phishing Defence Services

- Cyber Security Assessment & Audit

- Cyber Security Consultancy for i4.0 & e4.0

Corporate Sustainability

- ESG and Sustainability Services

- Manufacturing Technology (Tooling, Metals & Plastics) Recognition of Prior Learning (RPL) Mechanism

- Market Research and Analytics

- Business Innovation

- Sustainability-related standards and guidance

- Organisation Innovation Capability Development

- District Innovation

- Customer Service Assessment

- Intellectual Property (IP) Protection and Management

- Support to Creative Industries

- Manufacturing Standards Consultancy Service

- Production Capacity Optimisation

- Cost of Quality

Support Centres

- Low-altitude Economy Tech Hall

- The Cradle – Go Global Service Centre

- Agentic AI and Industrial Metaverse Hall

- HKPC-HP 3D Printing Technology Centre

- Future Manufacturing Hall

- Hong Kong Technology and Innovation Support Centre

- Inno Space

- The HATCH

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

Accumulative Roll Bonding (ARB) and Stamping Technologies for Multi-Metallic Composite Sheet

ARB technology offers higher flexibility in bonding of different metallic materials and cost-effectiveness for in-house batch production of composite alloy sheets. Such sheets with customised and strengthened mechanical properties can be volume produced for stamping of products with different enhanced functional requirements mix, such as 5G aluminum-copper lightweight communication devices with excellent heat dissipation, magnesium-steel aircraft and satellite electronic equipment casing with good magnetic shielding and stiffness, and aluminum-steel critical automobile components with light-weight and high strength.

Service Details:

- License of ARB forming technology for in-house production of hybrid material parts;

- Dedicated part design and stamping optimisation for forming of ARB alloy sheets;

- ARB alloy sheet and stamping die design and fabrication;

- ARB forming machinery / auxiliary production equipment set up and ARB parameters optimisation;

- ARB alloy sheet and stamping part prototypes making, small lot production and functional testing;

- Consultancy and training for technology adoption & operations.

Accumulative Roll Bonding Machine Developed by HKPC

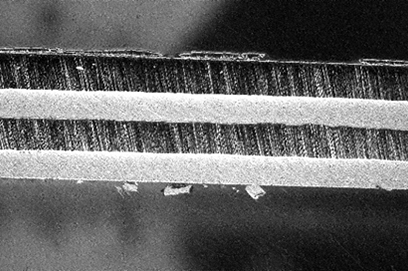

Stainless steel – aluminum ARB sheet

Stainless steel – aluminum ARB sheet

Carbon steel – steel ARB sheet

Accumulative Roll Bonding

Servo-drive stamping

Steel-aluminum-steel-aluminum ARB sheet

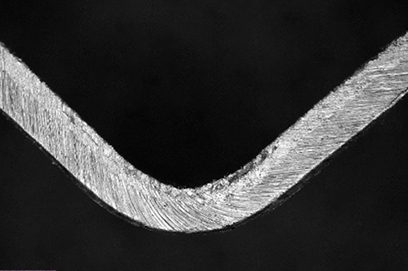

90° bending sample of steel-aluminum ARB sheet

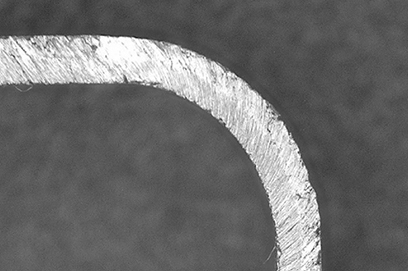

Radius bending sample of steel-aluminum ARB sheet

Share the latest information of HKPC to your inbox

Our Services

Support & Resource

HKPC Spotlights

COPYRIGHT© Hong Kong Productivity Council