-

Our Services

- AI with HKPC PICASSO

- The Cradle – Go Global Service Centre

-

New Industrialisation

- New Industrialisation

- New Productive Forces Service Platform

- Smart Production Line

- Innovation Technology and R&D

- Transformation and Upgrading

- Nurture New Industrialisation Talent

- Rules and Regulations

-

HealthTech and Traditional Chinese Medicine

- HealthTech and Traditional Chinese Medicine

- R&D service and Functional Investigation on Chinese Medicine, Health Food & Wellness product

- Compliance Consultation Service for Chinese Medicine, Pharmaceutical, Health Food and Medical Device Industries

- Manufacturing Enhancement - Automatic Intelligent System for Production and Packaging in Chinese Medicine, Pharmaceutical and Health Food Industries

- Assisting funding application for local medicine and health industrial associations

- “The Cradle” Services for Health Tech and TCM Industry

-

Smart Manufacturing

- Smart Manufacturing

-

IIOT

- IIOT

- Industrie 4.0 - Smart Enterprise

- Product Lifecycle Management Consultancy

- Intelligent Automatic Warehousing and Logistics

- Real-Time Manufacturing Tracking System

- Knowledge Based Engineering & CAD Solution

- Location Based Services and Location Analytics

- The HATCH

- Hong Kong Industrial Drone Technology Centre

- Novel Materials

-

Advanced Manufacturing Technology

- Advanced Manufacturing Technology

- 3D Scanning and Reverse Engineering Service

- Flexible Metallic Fiber Physical Porous Part Fabrication Technology

- Advanced Mould Cooling Technology and CAE Conformal Cooling Analysis

- Gas Atomisation Technology

- Dual Laser Metal Polishing Technology

- Advanced Additive Manufacturing, 3D Printing Technology, and Direct Manufacturing

- Diffusion Bonding Technology

- Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

- Plastic Process and Machinery Technology

- Fashion and Garment Technology

- Computer Aided Technology (CAx)

- Watch Assembly Automation Technology

-

Digital Transformation

- Digital Transformation

- HKPC Digital DIY Portal

- Digital Transformation Support

- Intelligent Integrated Non-wearable and Wearable Health Monitoring System and App for Elderly Homes

- 「FitEasy」Virtual Fitting Technology - For People with Disability

- Smart Solution

- Research and Analytics

- Strategic IT Management

- Embedded Software System

- New Media and Learning Technology Development

- IT Industry Support

- DevOps Maturity Assessment and Consultancy Service

- Software Testing Automation Consultancy Service

- Blockchain Consulting Service

- Extended Reality (XR) technology and consultancy service

-

Cyber Security

- Cyber Security

- Cyber Security

- Cybers Security-by-design, Privacy and Compliance-by-default

- Design & Architecture

- Train & Develop

- Offensive Security

- Intelligent Security

- Defensive Security

- Intelligent Hardening

- Internet of Things (IoT) & Operational Technology (OT) Cyber Security Testing

- Phishing Defence Services

- Cyber Security Assessment & Audit

- Cyber Security Consultancy for i4.0 & e4.0

-

Green & Smart Living

- Green & Smart Living

- Green Technology

- Food Technology

- Smart Living

-

Corporate Sustainability

- Corporate Sustainability

- ESG and Sustainability Services

- Manufacturing Technology (Tooling, Metals & Plastics) Recognition of Prior Learning (RPL) Mechanism

- Market Research and Analytics

- Business Innovation

- Sustainability-related standards and guidance

- Organisation Innovation Capability Development

- District Innovation

- Customer Service Assessment

- Intellectual Property (IP) Protection and Management

- Support to Creative Industries

- Manufacturing Standards Consultancy Service

- Production Capacity Optimisation

- Cost of Quality

- HKPC Academy

- SME Support

- Funding

- Testing & Standards

- Venues & Facilities

-

Support & Resource

- Technology Transfer

-

Support Centres

- Support Centres

- Low-altitude Economy Tech Hall

- The Cradle – Go Global Service Centre

- Agentic AI and Industrial Metaverse Hall

- HKPC-HP 3D Printing Technology Centre

- Future Manufacturing Hall

- Hong Kong Technology and Innovation Support Centre

- Inno Space

- The HATCH

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

- Testing & Standards

- HKPC Spotlights

- About US

-

LANGUAGE

LANGUAGE

HealthTech and Traditional Chinese Medicine

- R&D service and Functional Investigation on Chinese Medicine, Health Food & Wellness product

- Compliance Consultation Service for Chinese Medicine, Pharmaceutical, Health Food and Medical Device Industries

- Manufacturing Enhancement - Automatic Intelligent System for Production and Packaging in Chinese Medicine, Pharmaceutical and Health Food Industries

- Assisting funding application for local medicine and health industrial associations

- “The Cradle” Services for Health Tech and TCM Industry

IIOT

- Industrie 4.0 - Smart Enterprise

- Product Lifecycle Management Consultancy

- Intelligent Automatic Warehousing and Logistics

- Real-Time Manufacturing Tracking System

- Knowledge Based Engineering & CAD Solution

- Location Based Services and Location Analytics

- The HATCH

- Hong Kong Industrial Drone Technology Centre

Advanced Manufacturing Technology

- 3D Scanning and Reverse Engineering Service

- Flexible Metallic Fiber Physical Porous Part Fabrication Technology

- Advanced Mould Cooling Technology and CAE Conformal Cooling Analysis

- Gas Atomisation Technology

- Dual Laser Metal Polishing Technology

- Advanced Additive Manufacturing, 3D Printing Technology, and Direct Manufacturing

- Diffusion Bonding Technology

- Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

- Plastic Process and Machinery Technology

- Fashion and Garment Technology

- Computer Aided Technology (CAx)

- Watch Assembly Automation Technology

Digital Transformation

- HKPC Digital DIY Portal

- Digital Transformation Support

- Intelligent Integrated Non-wearable and Wearable Health Monitoring System and App for Elderly Homes

- 「FitEasy」Virtual Fitting Technology - For People with Disability

- Smart Solution

- Research and Analytics

- Strategic IT Management

- Embedded Software System

- New Media and Learning Technology Development

- IT Industry Support

- DevOps Maturity Assessment and Consultancy Service

- Software Testing Automation Consultancy Service

- Blockchain Consulting Service

- Extended Reality (XR) technology and consultancy service

Cyber Security

- Cyber Security

- Cybers Security-by-design, Privacy and Compliance-by-default

- Design & Architecture

- Train & Develop

- Offensive Security

- Intelligent Security

- Defensive Security

- Intelligent Hardening

- Internet of Things (IoT) & Operational Technology (OT) Cyber Security Testing

- Phishing Defence Services

- Cyber Security Assessment & Audit

- Cyber Security Consultancy for i4.0 & e4.0

Corporate Sustainability

- ESG and Sustainability Services

- Manufacturing Technology (Tooling, Metals & Plastics) Recognition of Prior Learning (RPL) Mechanism

- Market Research and Analytics

- Business Innovation

- Sustainability-related standards and guidance

- Organisation Innovation Capability Development

- District Innovation

- Customer Service Assessment

- Intellectual Property (IP) Protection and Management

- Support to Creative Industries

- Manufacturing Standards Consultancy Service

- Production Capacity Optimisation

- Cost of Quality

Support Centres

- Low-altitude Economy Tech Hall

- The Cradle – Go Global Service Centre

- Agentic AI and Industrial Metaverse Hall

- HKPC-HP 3D Printing Technology Centre

- Future Manufacturing Hall

- Hong Kong Technology and Innovation Support Centre

- Inno Space

- The HATCH

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

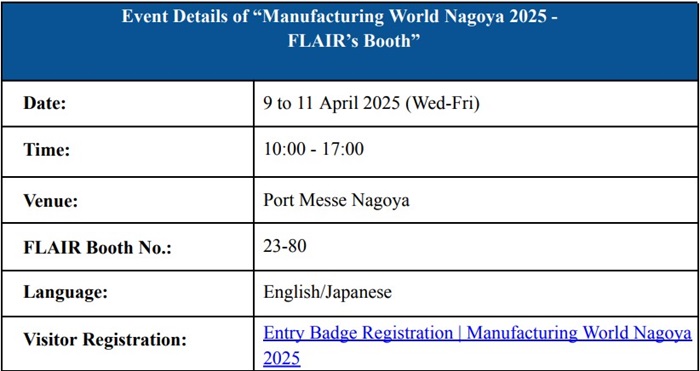

FLAIR to Debut at Manufacturing World Nagoya 2025 Showcasing Five Platform Technologies to Empower Industrial Advancement in the Central Japan Region

【Hong Kong | 8 April 2025】The Hong Kong Industrial Artificial Intelligence and Robotics Centre (FLAIR) will make its debut in the Japanese market by participating in Manufacturing World Nagoya 2025, held at Port Messe Nagoya from 9 to 11 April 2025. FLAIR will showcase its advanced technologies and innovative solutions to the manufacturing sector in Japan, aiming to foster strategic collaborations and drive industrial innovation.

Manufacturing World Nagoya 2025: Inspiring Innovation and Uncovering New Opportunities in Manufacturing

Nagoya, a key manufacturing hub in Central Japan, is renowned for its automotive, aerospace, and heavy industries. As Central Japan's largest manufacturing trade show, Manufacturing World Nagoya 2025 will showcase cutting-edge technologies and latest manufacturing trends across various fields, including mechanical components, factory equipment, additive manufacturing, digital transformation (DX) solutions, and industrial cyber security. The event is expected to attract over 30,000 professional visitors, representing design, development, manufacturing, production engineering, purchasing, and information systems departments within the manufacturing sector. The exhibition provides exhibitors with exceptional networking, business development, and learning opportunities, complemented by conferences where attendees can gain insights from industry experts and stay abreast of the latest advancements.

FLAIR to Empower Japan’s Manufacturing Industry with Advanced Technologies and Intelligent Solutions

At the exhibition, FLAIR will showcase its mature industrial AI solutions and actively seek partnerships with leading manufacturing companies in the Chubu region. Recognising the region's significance as the heart of Japan's manufacturing industry, FLAIR aims to share its expertise in industrial AI and robotics, helping local businesses address increasing global competition, enhance production efficiency, and improve product quality. Furthermore, FLAIR seeks to establish long-term collaborations with potential clients, strategic partners, and distributors to drive innovation and development within the Chubu region's manufacturing sector, fostering mutual success.

FLAIR will highlight its five commercially established spin-off companies and their AI solutions, which address critical industry challenges. These solutions span five key areas: visual inspection, industrial product creation, next-generation warehouse logistics, low-code robotics, and sustainable green technologies, offering comprehensive support for the future of manufacturing.(See appendix for details)

FLAIR's International R&D Team: Pioneering Industrial AI Innovation and Driving Global Transformation

FLAIR's international R&D team brings together top global talent with deep expertise in AI, computer vision, and robotics. The team is dedicated to developing innovative AI solutions tailored to diverse industrial applications and expanding their global influence through commercialisation.

Backed by its world-class R&D team, FLAIR has earned numerous international accolades, including patents and inventions such as the Hong Kong ICT Awards 2024 Gold Award for ICT Startup (Hardware and Devices), the APEC INPUT2 Start-Up Award, the TechConnect Global Innovation Award, and a win at the APICTA Awards 2024. These achievements underscore FLAIR's position as a leader in industrial AI innovation.

Visit FLAIR at Manufacturing World Nagoya 2025

FLAIR booth location: 23-80 at Manufacturing DX Expo

Visitor registration: Entry Badge Registration | Manufacturing World Nagoya 2025

- Ends -

Media Inquiries

For more information and the press release,

please visit: bit.ly/PP_FLAIR1227C_NAGOYA2025

Appendix - Highlights of FLAIR's Five Platforms:(For Full Introduction, please CLICK HERE):

- Vision Inspection Platform: A one-stop, no-code online platform for building AI vision inspection models, drastically reducing inspection costs and improving product quality across manufacturing, logistics, and other industries.

- Product Creation Platform: Automates assembly sequence planning, shortening product development cycles, reducing design iterations, and improving assembly efficiency for faster response to market needs.

- Logistics Platform: One of the first tools on the market to offer real-time bottleneck analysis. AI-powered insights and decision support improve logistics planning and operations efficiency, reducing operating costs.

- Robotics Platform: Exclusive features to provide a holistic approach and cyber-physical experience. Simplifies robot system development and deployment, and reduces development time and cost, making robotics accessible to more businesses to enhance automation.

- Sustainability Platform: Optimises waste management with AI-powered solutions such as intelligent waste sorting systems (“ULTRASORT”). Improves recycling efficiency, reduces pollution, and integrates with industrial control systems (SCADA) to optimise production processes and reduce energy consumption, driving towards sustainable development.

Share the latest information of HKPC to your inbox

Our Services

Support & Resource

HKPC Spotlights

COPYRIGHT© Hong Kong Productivity Council