HKPC’s Pioneering R&D Innovation in Industrial Metaverse Smart Production Line Enhances Local Enterprise’ Competitiveness as Forerunner in Digital Smart Factory Trend

(Hong Kong, 14 April 2023) The Hong Kong Productivity Council (HKPC) recently signed an agreement with Tung Hing Automation Investment Limited (Tung Hing) to leverage the jointly developed "Electrically-Assisted Free Forming (EAFF) Technology", create its Digital Twin in the virtual space of industrial metaverse. This will provide the first smart production solution in Hong Kong based on a Cyber-Physical System (CPS), integrating real-time data exchange between physical and virtual production processes. Through the industrial metaverse, which eliminates geographic and spatial limitations, enterprises can optimise their production processes and offer training to their technical personnel. The industrial metaverse technology can also facilitate multiple parties to conduct real-time remote maintenance, enabling technical personnel to remotely troubleshoot and repair equipment from different locations, reducing downtime and maintenance costs. The collaboration can help enterprises explore new opportunities and innovate their business models. The initiative also carries on HKPC’s efforts to support the industry to make proactive deployment to follow the future trend of smart manufacturing, promote new industrialisation in Hong Kong and create value for the industry.

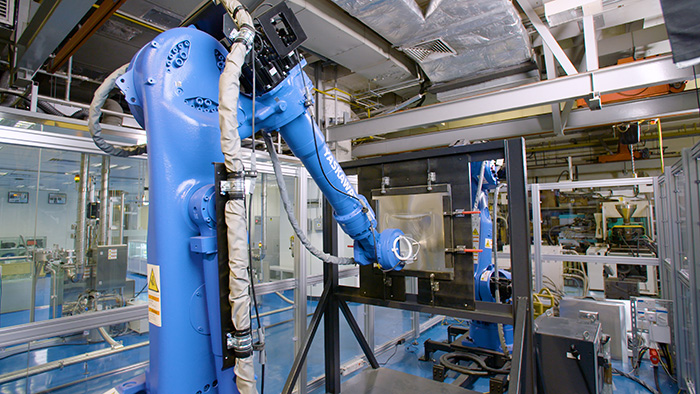

Tung Hing is an industrial automation control equipment supplier and system integrator in Hong Kong, providing technology and services such as smart production line design, artificial intelligence, and industrial robots. The patented EAFF Technology is jointly developed by HKPC and Tung Hing with funding support from the Innovation and Technology Fund of the Innovation and Technology Commission. This innovation has won awards at various international and prestigious technological R&D events such as the “R&D 100 Awards”, “2021 Geneva International Exhibition of Inventions”, and “IMechE Project Award”. EAFF technology employs a virtualisation technology to perform dieless forming by analysing the 3D model provided and using two cooperating 6-axis robot arms. The simulation of the dieless forming process imitates the robot movement and performs finite element analysis of the stress distribution, heat transfer and electrical effect of deformed material which is invaluable for process optimisation and product realisation. Moreover, it is especially suitable for producing parts with complex geometry (including undercut features). The streamlined production process can be shortened up to 10 times from the original 8-15 weeks, reducing both product development and production time significantly. In addition, a wider choice of materials is available, meaning there is more room for design possibilities.

Under the latest agreement, HKPC and Tung Hing will collaborate again to integrate the EAFF technology into industrial metaverse by creating a Digital Twin of the physical EAFF unit located at HKPC. Digital Twin refers to the digital representation of a physical object. Through methods such as Industrial Internet of Things (IIoT), simulation technology, 3D modelling technology, and Virtual Reality (VR), various attributes of a physical system are mapped to a virtual space, reflecting the real-time status of the actual machinery and equipment. With Digital Twin technology, enterprises can be unrestricted by time and location in terms of production progress. They can examine the best production processes and simulate product conditions in virtual space. On the other hand, Digital Twin technology also enables real-time remote maintenance and repair of equipment, reducing downtime and maintenance costs. If the equipment is not located on-site or needs to be shipped to another location, this technology can dispense with the traditional process of deploying engineering personnel to remote locations for equipment inspection and on-site parts replacement, as well as the delays and high costs associated with it. Furthermore, it can provide a virtual platform for multi-party collaboration among technical personnel and for training purposes, enhancing the competitiveness of enterprises. Leveraging its internationally renowned industrial metaverse technology capabilities and comprehensive facilities, HKPC will showcase its Digital Twin technology in the newly established “Celesphere”. The demonstration will feature a smart production line by combining relevant software and hardware, and provide Tung Hing with end-to-end support services, including design, operation, technical personnel training, and equipment optimisation. HKPC is dedicated to providing industrial metaverse technology services to the industry and promoting the widespread adoption of it. By unlocking the power of industrial metaverse technology, this collaboration aims to join hands with enterprises to build a new ecosystem for industrial development.

Mr Edmond LAI, Chief Digital Officer of HKPC, stated that, "As the first research institution in Hong Kong to promote the practical application of industrial metaverse technology, HKPC, in collaboration with Tung Hing, will use our complementary strengths to solve the long-standing pain points of high investment costs and low operating efficiency faced by the industry. By leveraging industrial metaverse technology, this collaboration aims to connect physical production lines with the metaverse for building, testing, and optimisation, which can reduce energy consumption and other resource inputs such as equipment maintenance, thereby lowering costs. Moreover, the collaboration also supports enterprises to train technical personnel in the metaverse, helping to achieve sustainable development and identify new business models, paving the way for the transition to become smart factories of the future. With the development of the first industrial metaverse smart production line officially kicking off, HKPC will continue to promote and realise the application of industrial metaverse technology in the local industry, contributing to the development of new industrialisation.”

Mr Roy LIM, Vice President of Tung Hing, said, “Tung Hing fully supports the implementation of the ‘Hong Kong Innovation & Technology Development Blueprint’. And we are pleased to continue collaborating with HKPC to promote the application of industrial metaverse technology and in doing so, to also assist the manufacturing industry in creating added value and moving towards ‘Industry 4.0’ smart manufacturing, and bolster new industrialisation in Hong Kong. Through the application of industrial metaverse technology, the collaboration aims to establish a three-dimensional industrial digital model and quickly set up production scenarios using Digital Twin technology to assist enterprises in completing the layout design and logistics inspection of factories and production lines. Professional offline programming is used to conduct virtual debugging of robots and establish data interconnection with production line equipment, achieving real-time synchronisation between the virtual and physical equipment. The technology can also be used for process parameter debugging during R&D and production, promoting digitalisation and smart factory development and system optimisation, which can help enhance production capacity and efficiency as well as reduce costs."

“Celesphere” is Hong Kong’s first technology hall themed in industrial metaverse. For more information about the hall or to book a visit, please refer to: https://www.hkpc.org/en/support-resource/support-centers/celesphere.

- Ends -

HKPC collaborates with Tung Hing to introduce industrial metaverse development for innovative “Electrically-Assisted Free Forming (EAFF) Technology”, providing Hong Kong's first smart production solution based on a Cyber-Physical System CPS. This initiative supports the industry to make proactive deployment to follow the future trend of smart manufacturing, promote Hong Kong's new industrialisation, and create value for the industry. Mr Raymond SHAN, General Manager, Greater Bay Area Business Development of HKPC (right), and Mr Roy LIM, Vice President of Tung Hing (left), sign the agreement.

HKPC collaborates with Tung Hing to introduce industrial metaverse development for innovative “Electrically-Assisted Free Forming (EAFF) Technology”, providing Hong Kong's first smart production solution based on a Cyber-Physical System CPS. This initiative supports the industry to make proactive deployment to follow the future trend of smart manufacturing, promote Hong Kong's new industrialisation, and create value for the industry. Mr Raymond SHAN, General Manager, Greater Bay Area Business Development of HKPC (right), and Mr Roy LIM, Vice President of Tung Hing (left), sign the agreement.

HKPC will collaborate with Tung Hing to integrate the existing EAFF technology into the industrial metaverse, leveraging Digital Twin technology to reflect the real-time status of the machinery and testing the optimal production processes and simulating product conditions in a virtual space, as well as facilitate real-time remote maintenance with multiple parties, unrestricted by time and location.

HKPC will collaborate with Tung Hing to integrate the existing EAFF technology into the industrial metaverse, leveraging Digital Twin technology to reflect the real-time status of the machinery and testing the optimal production processes and simulating product conditions in a virtual space, as well as facilitate real-time remote maintenance with multiple parties, unrestricted by time and location.

Share the latest information of HKPC to your inbox

LANGUAGE

LANGUAGE