-

Our Services

- The Cradle – Go Global Service Centre

-

New Industrialisation

- New Industrialisation

- New Productive Forces Service Platform

- Smart Production Line

- Innovation Technology and R&D

- Transformation and Upgrading

- Nurture New Industrialisation Talent

- Rules and Regulations

-

HealthTech and Traditional Chinese Medicine

- HealthTech and Traditional Chinese Medicine

- R&D service and Functional Investigation on Chinese Medicine, Health Food & Wellness product

- Compliance Consultation Service for Chinese Medicine, Pharmaceutical, Health Food and Medical Device Industries

- Manufacturing Enhancement - Automatic Intelligent System for Production and Packaging in Chinese Medicine, Pharmaceutical and Health Food Industries

- Assisting funding application for local medicine and health industrial associations

- “The Cradle” Services for Health Tech and TCM Industry

-

Smart Manufacturing

- Smart Manufacturing

-

IIOT

- IIOT

- Industrie 4.0 - Smart Enterprise

- Product Lifecycle Management Consultancy

- Intelligent Automatic Warehousing and Logistics

- Real-Time Manufacturing Tracking System

- Knowledge Based Engineering & CAD Solution

- Location Based Services and Location Analytics

- The HATCH

- Hong Kong Industrial Drone Technology Centre

-

AI & Robotics

- AI & Robotics

- AI Sheet Metal Surface Defect Detection Technology

- Product Innovation and Design Management

- Robotics Application

- Automation Feasibility Study

- 3D Automatic Processing

- Application and Research on Vision and Ultrasonic Inspection Assisted by Artificial Intelligence and Robotics

- Customized Intelligent and Cognition Automation Machine & System Development

- Autonomous Air-ground Cooperative Tunnel Inspector

- AR-Empowered Robot Control System (ARERC System)

- IoT-enabled Smart Toilet Bowl Cleaning System

- Novel Materials

-

Advanced Manufacturing Technology

- Advanced Manufacturing Technology

- 3D Scanning and Reverse Engineering Service

- Flexible Metallic Fiber Physical Porous Part Fabrication Technology

- Advanced Mould Cooling Technology and CAE Conformal Cooling Analysis

- Gas Atomisation Technology

- Dual Laser Metal Polishing Technology

- Advanced Additive Manufacturing, 3D Printing Technology, and Direct Manufacturing

- Diffusion Bonding Technology

- Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

- Plastic Process and Machinery Technology

- Fashion and Garment Technology

- Computer Aided Technology (CAx)

- Watch Assembly Automation Technology

-

Digital Transformation

- Digital Transformation

- HKPC Digital DIY Portal

- Digital Transformation Support

- Intelligent Integrated Non-wearable and Wearable Health Monitoring System and App for Elderly Homes

- 「FitEasy」Virtual Fitting Technology - For People with Disability

- Smart Solution

- Research and Analytics

- Strategic IT Management

- Embedded Software System

- New Media and Learning Technology Development

- IT Industry Support

- DevOps Maturity Assessment and Consultancy Service

- Software Testing Automation Consultancy Service

- Blockchain Consulting Service

- Extended Reality (XR) technology and consultancy service

-

Cyber Security

- Cyber Security

- Cyber Security

- Cybers Security-by-design, Privacy and Compliance-by-default

- Design & Architecture

- Train & Develop

- Offensive Security

- Intelligent Security

- Defensive Security

- Intelligent Hardening

- Internet of Things (IoT) & Operational Technology (OT) Cyber Security Testing

- Phishing Defence Services

- Cyber Security Assessment & Audit

- Cyber Security Consultancy for i4.0 & e4.0

-

Green & Smart Living

- Green & Smart Living

- Green Technology

- Food Technology

- Smart Living

-

Corporate Sustainability

- Corporate Sustainability

- ESG and Sustainability Services

- Manufacturing Technology (Tooling, Metals & Plastics) Recognition of Prior Learning (RPL) Mechanism

- Market Research and Analytics

- Business Innovation

- Sustainability-related standards and guidance

- Organisation Innovation Capability Development

- District Innovation

- Customer Service Assessment

- Intellectual Property (IP) Protection and Management

- Support to Creative Industries

- Manufacturing Standards Consultancy Service

- Production Capacity Optimisation

- Cost of Quality

- HKPC Academy

- SME Support

- Funding

- Testing & Standards

- Venues & Facilities

-

Support & Resource

- Technology Transfer

-

Support Centres

- Support Centres

- Low-altitude Economy Tech Hall

- The Cradle – Go Global Service Centre

- Agentic AI and Industrial Metaverse Hall

- HKPC-HP 3D Printing Technology Centre

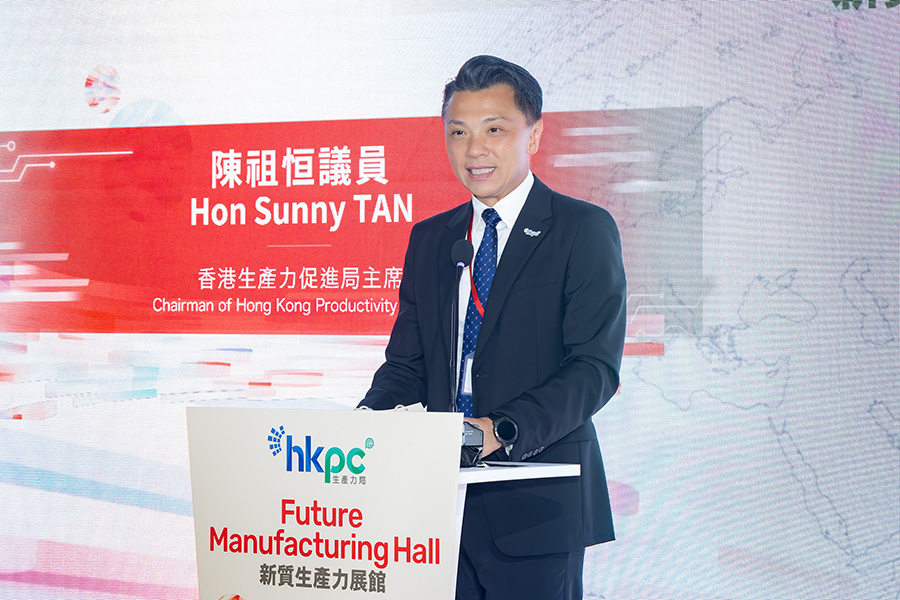

- Future Manufacturing Hall

- Hong Kong Technology and Innovation Support Centre

- Inno Space

- The HATCH

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

- Testing & Standards

- HKPC Spotlights

- About US

-

LANGUAGE

LANGUAGE

HealthTech and Traditional Chinese Medicine

- R&D service and Functional Investigation on Chinese Medicine, Health Food & Wellness product

- Compliance Consultation Service for Chinese Medicine, Pharmaceutical, Health Food and Medical Device Industries

- Manufacturing Enhancement - Automatic Intelligent System for Production and Packaging in Chinese Medicine, Pharmaceutical and Health Food Industries

- Assisting funding application for local medicine and health industrial associations

- “The Cradle” Services for Health Tech and TCM Industry

IIOT

- Industrie 4.0 - Smart Enterprise

- Product Lifecycle Management Consultancy

- Intelligent Automatic Warehousing and Logistics

- Real-Time Manufacturing Tracking System

- Knowledge Based Engineering & CAD Solution

- Location Based Services and Location Analytics

- The HATCH

- Hong Kong Industrial Drone Technology Centre

AI & Robotics

- AI Sheet Metal Surface Defect Detection Technology

- Product Innovation and Design Management

- Robotics Application

- Automation Feasibility Study

- 3D Automatic Processing

- Application and Research on Vision and Ultrasonic Inspection Assisted by Artificial Intelligence and Robotics

- Customized Intelligent and Cognition Automation Machine & System Development

- Autonomous Air-ground Cooperative Tunnel Inspector

- AR-Empowered Robot Control System (ARERC System)

- IoT-enabled Smart Toilet Bowl Cleaning System

Advanced Manufacturing Technology

- 3D Scanning and Reverse Engineering Service

- Flexible Metallic Fiber Physical Porous Part Fabrication Technology

- Advanced Mould Cooling Technology and CAE Conformal Cooling Analysis

- Gas Atomisation Technology

- Dual Laser Metal Polishing Technology

- Advanced Additive Manufacturing, 3D Printing Technology, and Direct Manufacturing

- Diffusion Bonding Technology

- Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

- Plastic Process and Machinery Technology

- Fashion and Garment Technology

- Computer Aided Technology (CAx)

- Watch Assembly Automation Technology

Digital Transformation

- HKPC Digital DIY Portal

- Digital Transformation Support

- Intelligent Integrated Non-wearable and Wearable Health Monitoring System and App for Elderly Homes

- 「FitEasy」Virtual Fitting Technology - For People with Disability

- Smart Solution

- Research and Analytics

- Strategic IT Management

- Embedded Software System

- New Media and Learning Technology Development

- IT Industry Support

- DevOps Maturity Assessment and Consultancy Service

- Software Testing Automation Consultancy Service

- Blockchain Consulting Service

- Extended Reality (XR) technology and consultancy service

Cyber Security

- Cyber Security

- Cybers Security-by-design, Privacy and Compliance-by-default

- Design & Architecture

- Train & Develop

- Offensive Security

- Intelligent Security

- Defensive Security

- Intelligent Hardening

- Internet of Things (IoT) & Operational Technology (OT) Cyber Security Testing

- Phishing Defence Services

- Cyber Security Assessment & Audit

- Cyber Security Consultancy for i4.0 & e4.0

Corporate Sustainability

- ESG and Sustainability Services

- Manufacturing Technology (Tooling, Metals & Plastics) Recognition of Prior Learning (RPL) Mechanism

- Market Research and Analytics

- Business Innovation

- Sustainability-related standards and guidance

- Organisation Innovation Capability Development

- District Innovation

- Customer Service Assessment

- Intellectual Property (IP) Protection and Management

- Support to Creative Industries

- Manufacturing Standards Consultancy Service

- Production Capacity Optimisation

- Cost of Quality

Support Centres

- Low-altitude Economy Tech Hall

- The Cradle – Go Global Service Centre

- Agentic AI and Industrial Metaverse Hall

- HKPC-HP 3D Printing Technology Centre

- Future Manufacturing Hall

- Hong Kong Technology and Innovation Support Centre

- Inno Space

- The HATCH

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

- Low-altitude Economy Tech Hall

- The Cradle – Go Global Service Centre

- Agentic AI and Industrial Metaverse Hall

- HKPC-HP 3D Printing Technology Centre

- Future Manufacturing Hall

- Hong Kong Technology and Innovation Support Centre

- Inno Space

- The HATCH

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

Future Manufacturing Hall

The purpose of setting up “Future Manufacturing Hall” (FM Hall) is to introduce the industries what “New Productive Forces” is, why it is important to them, and how they can achieve New Productive Forces by embracing technology and innovation.

To provide a more authentic experience to the public, especially for those from the industries, we will showcase success stories, and also the technologies and services HKPC can provide to the industries to help them achieve New Productive Forces in FM Hall, which in return, will drive economic growth in Hong Kong.

Our FM Hall is not only for Hong Kong public, but also welcomes people from Mainland and over the world. We believe HKPC’s technologies and services can also contribute the development of New Productive Forces in the Greater Bay Area, and even in the whole nation.

Exhibits Highlights

Microfactory

“Microfactory” refers to the ability to maximise production efficiency within a limited space by applying high-end intelligent technologies, empowering a new type of manufacturing model. Microfactory has the characteristics of customised, quick respond to the market, increasing space unit output value, hyper-local, and sustainable.

Taking the textile and garment industry as an example, traditionally, the production of a sweater requires multiple steps (including weaving, knitting, sewing, picking, ironing, etc.) and a large amount of manual labor. However, now through the application of disruptive production technologies and industrial Internet of Things (IoT), it is possible to achieve fully automated production from yarn to finished garments.

Advantages

- This model is characterised by small batch production, low inventory, and the ability to increase the productivity per unit of space.

- Enhancing production flexibility to meet diverse market demands while reducing inventory accumulation.

Introduction to Advanced Technology Videos

Hephaestus

The industrial artificial intelligence application platform integrates general industrial data, model training, inference and model cloud deployment, thereby reducing the difficulty of developing and applying Artificial Intelligence (AI) technology. This enables small and medium-sized enterprises without professional support to quickly get started.

Advantages

- Reduce the difficulty of using cutting-edge technologies

- Reduce time-to-production for cutting-edge technologies

- Improving the efficiency of SMEs

Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

The sheet metal is gradually deformed into the designed three-dimensional shape by two co-operating six-axis manipulators running on the two sides of the sheet metal which has been connected with electric current and following a pre-set track, it is especially suitable for manufacturing sheet metal with small batch production and complex shape.

Service Details

- To provide technical evaluation, technical design input, computer-aided engineering (CA) analyses and tool path design services for incremental forming of sheet metal

- Advanced six-axis manipulators pressurisation devices to assist industries in achieving small batch production and cost-effective customised sheet metal production

- Possess extensive technical knowledge for identifying and evaluating the application areas of electrically-assisted free forming technology, hands-on experience on complex tool path design and free forming production of sheet metal.

CAP Fresh- A Game Changing Cold Atmospheric Plasma Disinfection Technology for Fresh Food

A non-destructive physical treatment process to extend shelf life of food. Packaged fresh food or dry powdered spices are placed on conveyor belts, then being transported under the electrodes, then leveraging highly active charged particles, to kill bacteria and spore on food surface.

Advantages

- Extend the shelf life of fresh food by up to 300% and without adding any preservatives.

- Cold plasma can reduce a significant number of microbes on food, thereby ensuring food safety and protecting the health of members of the public.

- This technology is an environmentally friendly disinfection method, which can reduce energy consumption and food waste.

Theme Hall Highlights

Share the latest information of HKPC to your inbox

Our Services

Support & Resource

HKPC Spotlights

COPYRIGHT© Hong Kong Productivity Council