-

Our Services

- The Cradle – Go Global Service Centre

-

New Industrialisation

- New Industrialisation

- New Productive Forces Service Platform

- Smart Production Line

- Innovation Technology and R&D

- Transformation and Upgrading

- Nurture New Industrialisation Talent

- Rules and Regulations

-

HealthTech and Traditional Chinese Medicine

- HealthTech and Traditional Chinese Medicine

- R&D service and Functional Investigation on Chinese Medicine, Health Food & Wellness product

- Compliance Consultation Service for Chinese Medicine, Pharmaceutical, Health Food and Medical Device Industries

- Manufacturing Enhancement - Automatic Intelligent System for Production and Packaging in Chinese Medicine, Pharmaceutical and Health Food Industries

- Assisting funding application for local medicine and health industrial associations

- “The Cradle” Services for Health Tech and TCM Industry

-

Smart Manufacturing

- Smart Manufacturing

-

IIOT

- IIOT

- Industrie 4.0 - Smart Enterprise

- Product Lifecycle Management Consultancy

- Intelligent Automatic Warehousing and Logistics

- Real-Time Manufacturing Tracking System

- Knowledge Based Engineering & CAD Solution

- Location Based Services and Location Analytics

- The HATCH

- Hong Kong Industrial Drone Technology Centre

-

AI & Robotics

- AI & Robotics

- AI Sheet Metal Surface Defect Detection Technology

- Product Innovation and Design Management

- Robotics Application

- Automation Feasibility Study

- 3D Automatic Processing

- Application and Research on Vision and Ultrasonic Inspection Assisted by Artificial Intelligence and Robotics

- Customized Intelligent and Cognition Automation Machine & System Development

- Autonomous Air-ground Cooperative Tunnel Inspector

- AR-Empowered Robot Control System (ARERC System)

- IoT-enabled Smart Toilet Bowl Cleaning System

- Novel Materials

-

Advanced Manufacturing Technology

- Advanced Manufacturing Technology

- 3D Scanning and Reverse Engineering Service

- Flexible Metallic Fiber Physical Porous Part Fabrication Technology

- Advanced Mould Cooling Technology and CAE Conformal Cooling Analysis

- Gas Atomisation Technology

- Dual Laser Metal Polishing Technology

- Advanced Additive Manufacturing, 3D Printing Technology, and Direct Manufacturing

- Diffusion Bonding Technology

- Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

- Plastic Process and Machinery Technology

- Fashion and Garment Technology

- Computer Aided Technology (CAx)

- Watch Assembly Automation Technology

-

Digital Transformation

- Digital Transformation

- HKPC Digital DIY Portal

- Digital Transformation Support

- Intelligent Integrated Non-wearable and Wearable Health Monitoring System and App for Elderly Homes

- 「FitEasy」Virtual Fitting Technology - For People with Disability

- Smart Solution

- Research and Analytics

- Strategic IT Management

- Embedded Software System

- New Media and Learning Technology Development

- IT Industry Support

- DevOps Maturity Assessment and Consultancy Service

- Software Testing Automation Consultancy Service

- Blockchain Consulting Service

- Extended Reality (XR) technology and consultancy service

-

Cyber Security

- Cyber Security

- Cyber Security

- Cybers Security-by-design, Privacy and Compliance-by-default

- Design & Architecture

- Train & Develop

- Offensive Security

- Intelligent Security

- Defensive Security

- Intelligent Hardening

- Internet of Things (IoT) & Operational Technology (OT) Cyber Security Testing

- Phishing Defence Services

- Cyber Security Assessment & Audit

- Cyber Security Consultancy for i4.0 & e4.0

-

Green & Smart Living

- Green & Smart Living

- Green Technology

- Food Technology

- Smart Living

-

Corporate Sustainability

- Corporate Sustainability

- ESG and Sustainability Services

- Manufacturing Technology (Tooling, Metals & Plastics) Recognition of Prior Learning (RPL) Mechanism

- Market Research and Analytics

- Business Innovation

- Sustainability-related standards and guidance

- Organisation Innovation Capability Development

- District Innovation

- Customer Service Assessment

- Intellectual Property (IP) Protection and Management

- Support to Creative Industries

- Manufacturing Standards Consultancy Service

- Production Capacity Optimisation

- Cost of Quality

- HKPC Academy

- SME Support

- Funding

- Testing & Standards

- Venues & Facilities

-

Support & Resource

- Technology Transfer

-

Support Centres

- Support Centres

- Low-altitude Economy Tech Hall

- The Cradle – Go Global Service Centre

- Agentic AI and Industrial Metaverse Hall

- HKPC-HP 3D Printing Technology Centre

- Future Manufacturing Hall

- Hong Kong Technology and Innovation Support Centre

- Inno Space

- The HATCH

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

- Testing & Standards

- HKPC Spotlights

- About US

-

LANGUAGE

LANGUAGE

HealthTech and Traditional Chinese Medicine

- R&D service and Functional Investigation on Chinese Medicine, Health Food & Wellness product

- Compliance Consultation Service for Chinese Medicine, Pharmaceutical, Health Food and Medical Device Industries

- Manufacturing Enhancement - Automatic Intelligent System for Production and Packaging in Chinese Medicine, Pharmaceutical and Health Food Industries

- Assisting funding application for local medicine and health industrial associations

- “The Cradle” Services for Health Tech and TCM Industry

IIOT

- Industrie 4.0 - Smart Enterprise

- Product Lifecycle Management Consultancy

- Intelligent Automatic Warehousing and Logistics

- Real-Time Manufacturing Tracking System

- Knowledge Based Engineering & CAD Solution

- Location Based Services and Location Analytics

- The HATCH

- Hong Kong Industrial Drone Technology Centre

AI & Robotics

- AI Sheet Metal Surface Defect Detection Technology

- Product Innovation and Design Management

- Robotics Application

- Automation Feasibility Study

- 3D Automatic Processing

- Application and Research on Vision and Ultrasonic Inspection Assisted by Artificial Intelligence and Robotics

- Customized Intelligent and Cognition Automation Machine & System Development

- Autonomous Air-ground Cooperative Tunnel Inspector

- AR-Empowered Robot Control System (ARERC System)

- IoT-enabled Smart Toilet Bowl Cleaning System

Advanced Manufacturing Technology

- 3D Scanning and Reverse Engineering Service

- Flexible Metallic Fiber Physical Porous Part Fabrication Technology

- Advanced Mould Cooling Technology and CAE Conformal Cooling Analysis

- Gas Atomisation Technology

- Dual Laser Metal Polishing Technology

- Advanced Additive Manufacturing, 3D Printing Technology, and Direct Manufacturing

- Diffusion Bonding Technology

- Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

- Plastic Process and Machinery Technology

- Fashion and Garment Technology

- Computer Aided Technology (CAx)

- Watch Assembly Automation Technology

Digital Transformation

- HKPC Digital DIY Portal

- Digital Transformation Support

- Intelligent Integrated Non-wearable and Wearable Health Monitoring System and App for Elderly Homes

- 「FitEasy」Virtual Fitting Technology - For People with Disability

- Smart Solution

- Research and Analytics

- Strategic IT Management

- Embedded Software System

- New Media and Learning Technology Development

- IT Industry Support

- DevOps Maturity Assessment and Consultancy Service

- Software Testing Automation Consultancy Service

- Blockchain Consulting Service

- Extended Reality (XR) technology and consultancy service

Cyber Security

- Cyber Security

- Cybers Security-by-design, Privacy and Compliance-by-default

- Design & Architecture

- Train & Develop

- Offensive Security

- Intelligent Security

- Defensive Security

- Intelligent Hardening

- Internet of Things (IoT) & Operational Technology (OT) Cyber Security Testing

- Phishing Defence Services

- Cyber Security Assessment & Audit

- Cyber Security Consultancy for i4.0 & e4.0

Corporate Sustainability

- ESG and Sustainability Services

- Manufacturing Technology (Tooling, Metals & Plastics) Recognition of Prior Learning (RPL) Mechanism

- Market Research and Analytics

- Business Innovation

- Sustainability-related standards and guidance

- Organisation Innovation Capability Development

- District Innovation

- Customer Service Assessment

- Intellectual Property (IP) Protection and Management

- Support to Creative Industries

- Manufacturing Standards Consultancy Service

- Production Capacity Optimisation

- Cost of Quality

Support Centres

- Low-altitude Economy Tech Hall

- The Cradle – Go Global Service Centre

- Agentic AI and Industrial Metaverse Hall

- HKPC-HP 3D Printing Technology Centre

- Future Manufacturing Hall

- Hong Kong Technology and Innovation Support Centre

- Inno Space

- The HATCH

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

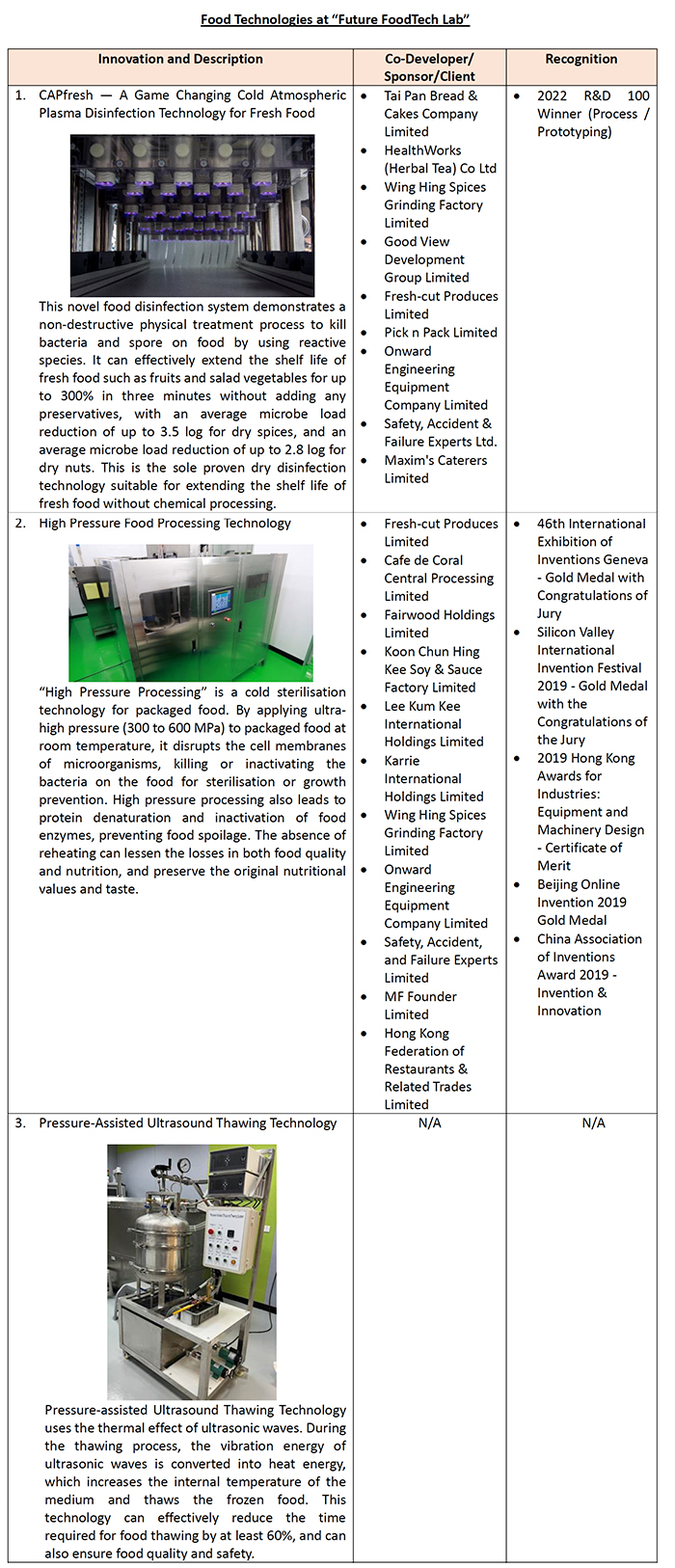

HKPC “Future FoodTech Lab” Opens Showcase World-leading, Award-winning Food Technologies Promote Reindustrialisation in Food Industry

(Hong Kong, 7 September 2022) The Hong Kong Productivity Council (HKPC) is committed to promoting the innovation and advancement of food technology (FoodTech) to enhance the productivity and competitiveness of the industry. Its new Future FoodTech Lab opened today to showcase world-leading novel food processing technologies with some being winners of international research awards. Ms Rebecca PUN, Commissioner for Innovation and Technology of the HKSAR Government, and Mr Sunny TAN, Chairman of HKPC, officiated its opening. Food industry leaders were also invited to share their insights on FoodTech development at the opening ceremony to encourage fellow industry peers to engage in advanced manufacturing and promote reindustrialisation in Hong Kong.

HKPC’s Future FoodTech Lab is Hong Kong’s first-ever FoodTech prototype display platform. Showcasing advanced FoodTech at different stages of the food supply chain, Future FoodTech Lab provides a platform for site visits and technology testing for the industry. The technologies at the lab will be updated regularly to keep the food industry abreast of the latest technology development. At present, the lab displays HKPC-developed food processing technologies, including Pressure-Assisted Ultrasound Thawing Technology, High Pressure Disinfection Technology, CAPfresh — A Game Changing Cold Atmospheric Plasma Disinfection Technology for Fresh Food, and Liquid Chilling Technology.

Ms Rebecca PUN, Commissioner for Innovation and Technology of the HKSAR Government, said, “In terms of technology support, HKPC provides a showcase platform for the industry to learn about new technologies in the food sector. In terms of funding, the Innovation and Technology Commission's Re-industrialisation Funding Scheme (RFS) subsidises manufacturers, on a 1 (Government):2 (Company) matching basis, to set up new smart production lines in Hong Kong. The funding for each project is capped at $15 million. RFS provides material assistance to local manufacturers, assisting them to move towards high value-added production and upgrade to Industry 4.0. I encourage the industry to leverage on the government's support in technology, capital and infrastructure to upgrade and transform in the process of ‘re-industrialisation’ so as to achieve greater success.”

Mr Sunny TAN, Chairman of HKPC, said, “The establishment of Future FoodTech Lab marks an important milestone for food industry development. HKPC hopes it can encourage the food industry to embrace advanced manufacturing and promote reindustrialisation in Hong Kong. Many of the food processing technologies showcased are ‘first-in-Hong Kong’ or even ‘world-leading’. For instance, CAPfresh — A Game Changing Cold Atmospheric Plasma Disinfection Technology for Fresh Food was recognised at the 2022 R&D 100 Awards in the United States. This is proof that Hong Kong’s R&D capabilities are of world-class level. HKPC will continue to meet the needs of the industry and provide appropriate support in the areas of technology, talent and capital, and promote the commercialisation of R&D results. In the long run, it will help the food industry to expand to the Greater Bay Area and overseas markets, thereby enabling ‘Made in Hong Kong’ brand to shine on the international stage.”

At the ceremony, Mr CHAN Ka-san, Director of 2 Plus 3 (HK) Industrial Company Limited, said, “At present, the company is mainly targeting the Hong Kong market, producing about 8,000 bottles of corn juice per week. We hope to expand our products to neighbouring cities and even overseas markets, but this has been limited by production capacity and shelf life. The intelligent production line whom we are setting up with the assistance of HKPC can effectively solve the above pain points. In addition to significantly raising the production capacity, it also improves the sterilisation process. The sterilisation parameters such as temperature, pressure, time, etc. are collected and monitored by intelligent sensors, which not only prolongs the life of the machine, but also ensures the reliability and stability of sterilisation and improves product quality and safety. Without the use of additives and preservatives, it is expected that the shelf life can be extended effectively.”

Mr YOUNG Kam-yim, Managing Director of Luen Tai Hong Kong Fresh Liquid Eggs Limited, said, “The traditional production process of fresh egg liquid needs to be completed manually and cannot raise productivity effectively. With intelligent production, the production capacity can increase by 2 to 3 times. At the same time, manpower, production time and human error will be reduced. Staff can also be re-assigned to handle high-tech work, reducing costs and raising efficiency. Intelligent production will also help diversify our business, expanding from B2B to B2C retail business.”

Mr OR Chun-ping, Chairman of Taste of Asia Group Limited, said, “Entering the digital era, we realise that the traditional food processing industry must move with the times in order to meet the food quality and safety demands of the market and consumers. During business expansion, we sought the help of HKPC to set up intelligent production line. HKPC’s highly experienced and skilled team introduced us to a complete and cost-effective intelligent solution, and assisted us in applying for government funding to enable the project to proceed smoothly, helping our enterprise maintain sustainable growth.”

Apart from technical support, HKPC also actively helps enterprises identify the appropriate government funding schemes to subsidise them to set up intelligent production lines locally. The above enterprise solutions have successfully applied or are currently applying for the Re-industrialisation Funding Scheme of the Innovation and Technology Commission of the HKSAR Government to help reduce production cost further and raise cost-effectiveness.

- Ends -

HKPC’s new Future FoodTech Lab opened today to showcase world-leading novel food processing technologies with some being winners of international research awards.

HKPC’s new Future FoodTech Lab opened today to showcase world-leading novel food processing technologies with some being winners of international research awards.

CAPfresh — A Game Changing Cold Atmospheric Plasma Disinfection Technology for Fresh Food was recognised at the 2022 R&D 100 Awards in the United States. This is proof that Hong Kong’s R&D capabilities are of world-class level.

CAPfresh — A Game Changing Cold Atmospheric Plasma Disinfection Technology for Fresh Food was recognised at the 2022 R&D 100 Awards in the United States. This is proof that Hong Kong’s R&D capabilities are of world-class level.

Ms Rebecca PUN, Commissioner for Innovation and Technology of the HKSAR Government (left) and Mr Sunny TAN, Chairman of HKPC (right) officiated the opening of Future FoodTech Lab.

Ms Rebecca PUN, Commissioner for Innovation and Technology of the HKSAR Government (left) and Mr Sunny TAN, Chairman of HKPC (right) officiated the opening of Future FoodTech Lab.

Group photo of officiating guests and food industry leaders at the opening of Future FoodTech Lab.

Group photo of officiating guests and food industry leaders at the opening of Future FoodTech Lab.

Food industry leaders shared their insights on FoodTech development at the opening ceremony to encourage fellow industry peers to engage in advanced manufacturing. (From left) Veteran media professional Mr Vincent WONG; Mr YOUNG Kam-yim, Managing Director of Luen Tai Hong Kong Fresh Liquid Eggs Limited; Mr CHAN Ka-san, Director of 2 Plus 3 (HK) Industrial Company Limited; Mr OR Chun-ping, Chairman of Taste of Asia Group Limited; and Ms Sonia LUI, Deputy Head, FoodTech Research and Management of HKPC

Food industry leaders shared their insights on FoodTech development at the opening ceremony to encourage fellow industry peers to engage in advanced manufacturing. (From left) Veteran media professional Mr Vincent WONG; Mr YOUNG Kam-yim, Managing Director of Luen Tai Hong Kong Fresh Liquid Eggs Limited; Mr CHAN Ka-san, Director of 2 Plus 3 (HK) Industrial Company Limited; Mr OR Chun-ping, Chairman of Taste of Asia Group Limited; and Ms Sonia LUI, Deputy Head, FoodTech Research and Management of HKPC

Share the latest information of HKPC to your inbox

Our Services

Support & Resource

HKPC Spotlights

COPYRIGHT© Hong Kong Productivity Council