-

Our Services

- The Cradle – Go Global Service Centre

-

New Industrialisation

- New Industrialisation

- New Productive Forces Service Platform

- Smart Production Line

- Innovation Technology and R&D

- Transformation and Upgrading

- Nurture New Industrialisation Talent

- Rules and Regulations

-

HealthTech and Traditional Chinese Medicine

- HealthTech and Traditional Chinese Medicine

- R&D service and Functional Investigation on Chinese Medicine, Health Food & Wellness product

- Compliance Consultation Service for Chinese Medicine, Pharmaceutical, Health Food and Medical Device Industries

- Manufacturing Enhancement - Automatic Intelligent System for Production and Packaging in Chinese Medicine, Pharmaceutical and Health Food Industries

- Assisting funding application for local medicine and health industrial associations

- “The Cradle” Services for Health Tech and TCM Industry

-

Smart Manufacturing

- Smart Manufacturing

-

IIOT

- IIOT

- Industrie 4.0 - Smart Enterprise

- Product Lifecycle Management Consultancy

- Intelligent Automatic Warehousing and Logistics

- Real-Time Manufacturing Tracking System

- Knowledge Based Engineering & CAD Solution

- Location Based Services and Location Analytics

- The HATCH

- Hong Kong Industrial Drone Technology Centre

-

AI & Robotics

- AI & Robotics

- AI Sheet Metal Surface Defect Detection Technology

- Product Innovation and Design Management

- Robotics Application

- Automation Feasibility Study

- 3D Automatic Processing

- Application and Research on Vision and Ultrasonic Inspection Assisted by Artificial Intelligence and Robotics

- Customized Intelligent and Cognition Automation Machine & System Development

- Autonomous Air-ground Cooperative Tunnel Inspector

- AR-Empowered Robot Control System (ARERC System)

- IoT-enabled Smart Toilet Bowl Cleaning System

- Novel Materials

-

Advanced Manufacturing Technology

- Advanced Manufacturing Technology

- 3D Scanning and Reverse Engineering Service

- Flexible Metallic Fiber Physical Porous Part Fabrication Technology

- Advanced Mould Cooling Technology and CAE Conformal Cooling Analysis

- Gas Atomisation Technology

- Dual Laser Metal Polishing Technology

- Advanced Additive Manufacturing, 3D Printing Technology, and Direct Manufacturing

- Diffusion Bonding Technology

- Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

- Plastic Process and Machinery Technology

- Fashion and Garment Technology

- Computer Aided Technology (CAx)

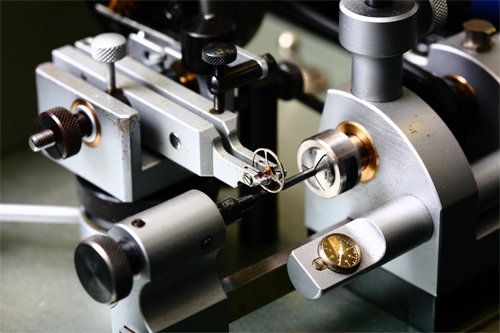

- Watch Assembly Automation Technology

-

Digital Transformation

- Digital Transformation

- HKPC Digital DIY Portal

- Digital Transformation Support

- Intelligent Integrated Non-wearable and Wearable Health Monitoring System and App for Elderly Homes

- 「FitEasy」Virtual Fitting Technology - For People with Disability

- Smart Solution

- Research and Analytics

- Strategic IT Management

- Embedded Software System

- New Media and Learning Technology Development

- IT Industry Support

- DevOps Maturity Assessment and Consultancy Service

- Software Testing Automation Consultancy Service

- Blockchain Consulting Service

- Extended Reality (XR) technology and consultancy service

-

Cyber Security

- Cyber Security

- Cyber Security

- Cybers Security-by-design, Privacy and Compliance-by-default

- Design & Architecture

- Train & Develop

- Offensive Security

- Intelligent Security

- Defensive Security

- Intelligent Hardening

- Internet of Things (IoT) & Operational Technology (OT) Cyber Security Testing

- Phishing Defence Services

- Cyber Security Assessment & Audit

- Cyber Security Consultancy for i4.0 & e4.0

-

Green & Smart Living

- Green & Smart Living

- Green Technology

- Food Technology

- Smart Living

-

Corporate Sustainability

- Corporate Sustainability

- ESG and Sustainability Services

- Manufacturing Technology (Tooling, Metals & Plastics) Recognition of Prior Learning (RPL) Mechanism

- Market Research and Analytics

- Business Innovation

- Sustainability-related standards and guidance

- Organisation Innovation Capability Development

- District Innovation

- Customer Service Assessment

- Intellectual Property (IP) Protection and Management

- Support to Creative Industries

- Manufacturing Standards Consultancy Service

- Production Capacity Optimisation

- Cost of Quality

- FutureSkills

- SME Support

- Funding

- Testing & Standards

- Venues & Facilities

-

Support & Resource

- Technology Transfer

-

Support Centres

- Support Centres

- Low-altitude Economy Tech Hall

- The Cradle – Go Global Service Centre

- Agentic AI and Industrial Metaverse Hall

- HKPC-HP 3D Printing Technology Centre

- Future Manufacturing Hall

- Hong Kong Technology and Innovation Support Centre

- Inno Space

- The HATCH

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

- Testing & Standards

- HKPC Spotlights

- About US

-

LANGUAGE

LANGUAGE

HealthTech and Traditional Chinese Medicine

- R&D service and Functional Investigation on Chinese Medicine, Health Food & Wellness product

- Compliance Consultation Service for Chinese Medicine, Pharmaceutical, Health Food and Medical Device Industries

- Manufacturing Enhancement - Automatic Intelligent System for Production and Packaging in Chinese Medicine, Pharmaceutical and Health Food Industries

- Assisting funding application for local medicine and health industrial associations

- “The Cradle” Services for Health Tech and TCM Industry

IIOT

- Industrie 4.0 - Smart Enterprise

- Product Lifecycle Management Consultancy

- Intelligent Automatic Warehousing and Logistics

- Real-Time Manufacturing Tracking System

- Knowledge Based Engineering & CAD Solution

- Location Based Services and Location Analytics

- The HATCH

- Hong Kong Industrial Drone Technology Centre

AI & Robotics

- AI Sheet Metal Surface Defect Detection Technology

- Product Innovation and Design Management

- Robotics Application

- Automation Feasibility Study

- 3D Automatic Processing

- Application and Research on Vision and Ultrasonic Inspection Assisted by Artificial Intelligence and Robotics

- Customized Intelligent and Cognition Automation Machine & System Development

- Autonomous Air-ground Cooperative Tunnel Inspector

- AR-Empowered Robot Control System (ARERC System)

- IoT-enabled Smart Toilet Bowl Cleaning System

Advanced Manufacturing Technology

- 3D Scanning and Reverse Engineering Service

- Flexible Metallic Fiber Physical Porous Part Fabrication Technology

- Advanced Mould Cooling Technology and CAE Conformal Cooling Analysis

- Gas Atomisation Technology

- Dual Laser Metal Polishing Technology

- Advanced Additive Manufacturing, 3D Printing Technology, and Direct Manufacturing

- Diffusion Bonding Technology

- Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

- Plastic Process and Machinery Technology

- Fashion and Garment Technology

- Computer Aided Technology (CAx)

- Watch Assembly Automation Technology

Digital Transformation

- HKPC Digital DIY Portal

- Digital Transformation Support

- Intelligent Integrated Non-wearable and Wearable Health Monitoring System and App for Elderly Homes

- 「FitEasy」Virtual Fitting Technology - For People with Disability

- Smart Solution

- Research and Analytics

- Strategic IT Management

- Embedded Software System

- New Media and Learning Technology Development

- IT Industry Support

- DevOps Maturity Assessment and Consultancy Service

- Software Testing Automation Consultancy Service

- Blockchain Consulting Service

- Extended Reality (XR) technology and consultancy service

Cyber Security

- Cyber Security

- Cybers Security-by-design, Privacy and Compliance-by-default

- Design & Architecture

- Train & Develop

- Offensive Security

- Intelligent Security

- Defensive Security

- Intelligent Hardening

- Internet of Things (IoT) & Operational Technology (OT) Cyber Security Testing

- Phishing Defence Services

- Cyber Security Assessment & Audit

- Cyber Security Consultancy for i4.0 & e4.0

Corporate Sustainability

- ESG and Sustainability Services

- Manufacturing Technology (Tooling, Metals & Plastics) Recognition of Prior Learning (RPL) Mechanism

- Market Research and Analytics

- Business Innovation

- Sustainability-related standards and guidance

- Organisation Innovation Capability Development

- District Innovation

- Customer Service Assessment

- Intellectual Property (IP) Protection and Management

- Support to Creative Industries

- Manufacturing Standards Consultancy Service

- Production Capacity Optimisation

- Cost of Quality

Support Centres

- Low-altitude Economy Tech Hall

- The Cradle – Go Global Service Centre

- Agentic AI and Industrial Metaverse Hall

- HKPC-HP 3D Printing Technology Centre

- Future Manufacturing Hall

- Hong Kong Technology and Innovation Support Centre

- Inno Space

- The HATCH

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

Smart Wearables, Watch and Clock

Smart Wearables, Watch & Clock Technology Centre

Smart Wearables, Watch and Clock Technology Centre provides a comprehensive range of consultancy and support services for the smart wearables, watch & clock industry. The Centre offers not only over 50 different independent testing services for traditional quartz and mechanical watches in compliance with international & Swiss standards, but also the smart wearable testing services, including the performance testing of devices for measuring steps, heart rates, blood pressure and oxygen content in blood.

Instrument of Testing Centre

| NAME OF INSTRUMENT | BRAND AND MODEL NUMBER |

|---|---|

| Water-resistance Testing System | 1) ROXER PX80 Water Pressure Tester |

| 2) SHEL LAB1225 Temperature Controlled Water Bath | |

| 3) Roxer, PR1 Heating Plate | |

| 4) Roxer, PV 25 Watch Case Leakage Tester | |

| Chronograph Aging Test / Pusher Aging Test | Chronofiable CP07 |

| Magnetic Field Resistance Testing System | Montena HC11 Helmholtz Coil |

| Shock Resistance Tester | ISA France 30 |

| Impact Tester | Chronofiable IT02 |

| Falling Steel Ball Tester for Watch glass | Chronofiable FB02 |

| Abrasion Resistance Tester | Polyservice D6 |

| Traction Tester | Wance ETM304 |

| Traction-Torsion Tester for Watch band | WatchLab Traction-Torsion Tester |

| Wet / Dry Friction Tester of leather / plastic strap | Chronofiable F |

| Ultra-violet light Tester | WatchLab UV Light Tester |

| Shaking Tester | Chronofiable S |

| Vibration Tester | Chronofiable V |

| Opening-Closing Testing Equipment for clasps | WatchLab OC-01 |

| Luminous Intensity Measurement Equipment | RC TRITEC MR photometer |

| Climatic chamber | Votsch VC4018, 4020 |

| Power-reserve & Winding Velocity Tester for a mechanical movement | VOH TWISTEST |

| Equipment for the functional index, Rate Measurement (Accuracy) for mechanical movement, watch | WITSCHI Chronoscope X1 |

| Equipment for the functional index, Rate Measurement (Accuracy), Electrical measurements for quartz movement, watch | WITSCHI Analyzer Q1 |

| Equipment for the 24-hour Current consumption measurement of quartz movement | Femto WatchLab System |

Support for Smart Wearables

Support for Smart Wearables

| A. General Test |

|---|

| 1. Water Resistance Test |

| 2. Shock Resistance Test |

| 3. Impact & Drop Test |

| 4. Traction Test (leather / plastic / metal) |

| 5. Traction & Torsion Test (leather / plastic) |

| 6. Dry/ Wet Friction Test (leather / plastic) |

| 7. Synthetic Sweat Test (leather / plastic) |

| 8. Shaking & Vibration Test |

| 9. Opening-closing Test |

| 10. UV Light Test (band / dial / hands) |

| 11. Temperature & Humidity Test |

| 12. Climatic Cycles Test |

| 13. Accuracy (Rate) Test |

| B. Electronic Performance |

|---|

| 1. Power Consumption |

| 2. RF Communication Range |

| 3. Electronic Reliability Test (EMC) |

| C. Regulatory Approval Pretest(CE/FCC Pretests) |

|---|

| 1. Bluetooth / NFC |

| 2. Zigbee / Z-Wave |

| 3. Wi-Fi |

| 4. Other Electronic Devices |

| D. Smart Wearables Performance Assessment |

|---|

| 1. Step-counting |

| 2. Heart Rate |

| 3. Blood Pressure |

| 4. Oxygen Content in Blood |

| 5. IoT Security |

Electronic/ Quartz / Mechanical / Automatic Watch Tests

Electronic/ Quartz / Mechanical / Automatic Watch Tests

| A. Watch Head |

|---|

| 1. Water Resistance Test |

| 2. Chronograph Aging Test |

| 3. Chronograph Aging Test |

| 4. Pusher Aging Test |

| 5. Magnetic Field Resistance Test |

| 6. Shock Resistance Test |

| 7. Impact Test |

| 8. Drop Test |

| 9. Vibration Test |

| B. Watch Glass / Crystal |

|---|

| 1. Push Out Crystal Test |

| 2. Resistance to a Falling Ball Test |

| 3. Hardness Test |

| C. Watch Case / Band / Dial / Hands |

|---|

| 1. Hardness Test (plastic case / band) |

| 2. Dip Test (plastic watch case / band) |

| 3. Abrasion Resistance Test |

| 4. Ageing Cycles on Bezel Ring |

| 5. Traction Test (leather / plastic / metal) |

| 6. Traction-torsion Test (leather / plastic) |

| 7. Traction-torsion Test (metal) |

| 8. Dry Friction Test (leather / plastic) |

| 9. Wet Friction Test (leather / plastic) |

| 10. Synthetic Sweat Test (leather / plastic) |

| 11. Shaking Test |

| 12. Opening-closing Test |

| 13. UV Light Test (band / dial / hands) |

| 14. Luminous Intensity Measurement |

| D. Watch Movement |

|---|

| 1. Electrical Measurement |

| 2. Current Consumption Measurement: 24 hours |

| 3. Functional Index-Rate Measurement |

| 4. Climatic Cycles Test |

| 5. High Temperature & Humidity Test |

| 6. Low Temperature Test |

| 7. Temperature & Humidity Test for 24 hours: customised conditions |

| 8. Power-reserve & Winding velocity test for a mechanical movement |

| 9. Chronometer Test for mechanical movement |

| 10. Chronometer Test for electronic/quartz movement |

| E. Movement Component |

|---|

| 1. 2D Measurements of Geometric Dimensions for positions, linear dimensions, diameter, arc, etc (1 attribute) |

| 2. 3D Measurements of Geometric Dimensions for runout, flatness, inclination angle, etc (1 attribute) |

| F. Movement Assemblies Quality |

|---|

| 1. Mechanical Movement Analysis by the acoustic signal from the rate measurement instrument |

| 2. Performance Test of barrel with mainspring |

| 3. Aging Test for hairspring/mainspring |

| 4. Aging Test of barrel with mainspring |

| 5. Traction Test for the attachment between hairspring and stud/hairspring and collet |

| 6. Loading Test on impulse pin and roller assembly |

| 7. Optical Measurement of Escapement mechanism |

| G. Electronic Performance |

|---|

| 1. Power Consumption |

| 2. Electronic Reliability Test (EMC) |

Plastic Materials Testing

| A. Mechanical Properties Test |

|---|

| 1. Tensile strength |

| 2. Compressive strength |

| 3. Impact strength |

| 4. Hardness |

| B. Electrical and Optical Properties Test |

|---|

| 1. Colour |

| 2. Colour difference |

| C. Degradable Test |

|---|

| 1. Thermal aging |

| 2. Accelerated aging (UV-A or L'V-B Exposure) |

| 3. Accelerated aging (Xenon Arc Lamp Exposure) |

| 4. Photodegradation |

| 5. Thermal degradation |

| D. Material Identification Test |

|---|

| 1. Density |

| 2. Specific gravity |

| 3. Material identification |

| 4. Plastics identification |

| 5. Glass fiber |

| 6. Moisture |

| E. Test Sample Preparation |

|---|

| 1. Standard test bar moulding |

Metal Materials Testing

| A. Electroplating Coating Testing |

|---|

| 1. Identification of Metallic Coating |

| 2. Corrosion Test |

| 3. Nickel Release Test |

| 4. Metal Content of Coating Alloy |

| 5. Hardness Test |

| B. Precious Metal Analysis |

|---|

| 1. Gold Content |

| 2. Sliver Content |

| 3. Palladium Content |

| 4. Platinum Content |

| 5. Other Metal Content |

| C. Plating Solution |

|---|

| 1. Trace amount Analysis of Metallic Contaminants in Plating Solution |

| 2. General Plating Solution |

SUBSCRIBE TO OUR NEWSLETTERS

Share the latest information of HKPC to your inbox

Our Services

Support & Resource

HKPC Spotlights

Privacy

Terms of Use

Occupational Health & Safety Policy

(PDF version)

Service Arrangement under Adverse Weather

Sitemap

Contact Us

COPYRIGHT© Hong Kong Productivity Council